Food & Drink

Technical Operator

The role of technical operator is to support the manufacture of quality food and drink products. They conduct start-up, close-down, changeover, and handovers in the manufacturing process, often using highly automated equipment and technology. They keep the manufacturing process running through operating machinery, front-line fault diagnosis and resolution, asset care, and performing basic maintenance.

A key focus for technical operators is food safety, through monitoring Hazard Analysis Critical Control Points and recording the results. As they operate in a regulated environment, they may be involved in conducting internal audits and supporting external audits to demonstrate compliance. Demonstrating compliance will also involve completing and updating documents, risk assessments, and completing traceability records. Food and drink manufacturing is often a team activity.

Technical operators may help to develop and support others through training and setting an example. They strive to continuously improve performance and quality (considering safety, quality, driving value). They support the implementation of new products or processes. During incidents, such as fires, accidents or near misses, they implement incident management procedures. Manufacturing process technicians will spend time on the production lines and off-line while working on activities such as projects.

They are likely to be required to work shifts, including unsociable hours. In their daily work, they interact with process operatives, other technical operators and site teams. This may include engineering, maintenance, quality, research and development, and packaging teams. They also interact with auditors, regulators and customers undertaking site visits. They typically report to an operational manager.

They work with minimal supervision. An employee in this occupation is responsible for working as part of a team to manufacture safe and compliant products. They need to meet deadlines, productivity, efficiency, hygiene, and environmental requirements, and ensure the health and safety of self and others.

Support

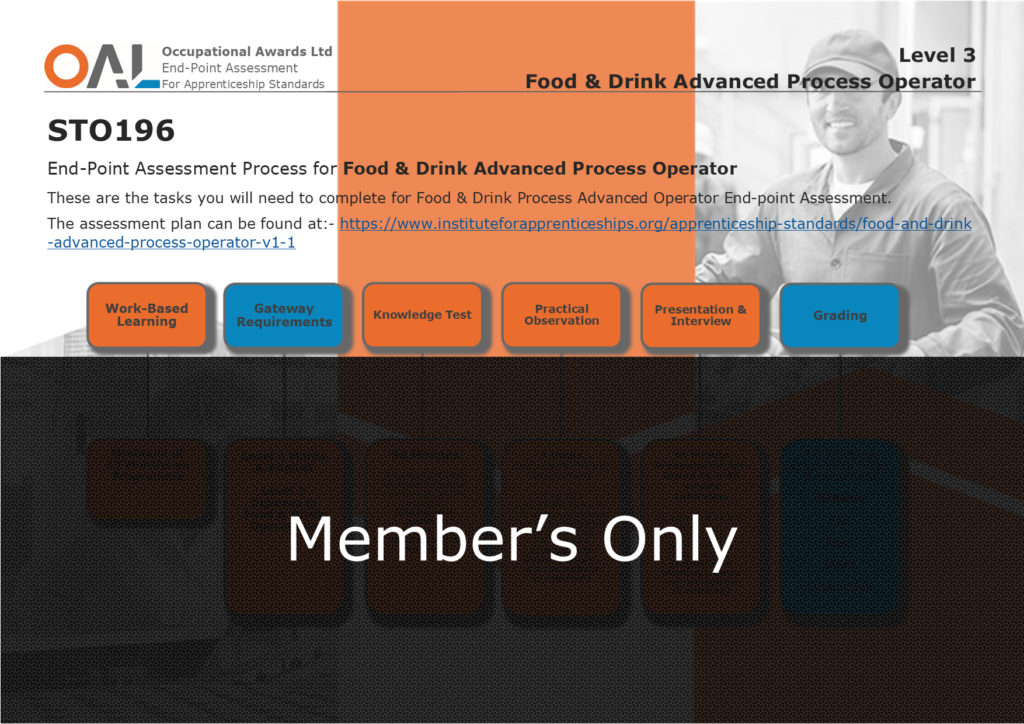

At OAL we are constantly working hard to ensure that we surpass the expectations of the institutions we work with. We intend to support apprentices on the pathway to EPA in any way we can towards a successful outcome. We have adapted various support materials like the process map to the left to make EPA as straightforward as it can be for apprentices and centres alike.